Digital Dentistry with 3D Printing

At our Dental-Lab, the well-being and safety of our patients is our priority. With the incorporation of 3D technology into our practice, we have the ability to offer faster and safer solutions.

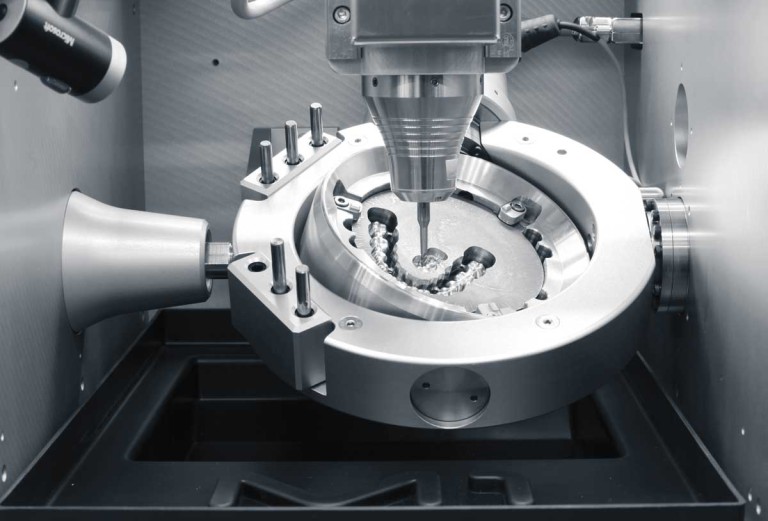

The new technologies and computer programs allow to obtain three-dimensional images of the mouth and the mouthparts in great detail. We are currently a full-service laboratory with 3D-Shape scanners, digital printing scanners, 3D printers that print partial crowns.

The use of CAD / CAM technology and oral scanning reduce patients’ fear, pain and inflammation. They also minimize errors and reduce intervention time thanks to previous study and diagnosis through three-dimensional images, allowing the dental laboratory to provide dental parts with exact precision.

On these three-dimensional images our specialist dentists can work as if from the same mouth outside, so that they can study, diagnose and plan comfortably (both for themselves and for the patient) the dental treatment that will be applied.

Full-Anatomical-Contour of Zirconium dioxide (FZ) Prettau ZirkonZahn.

The Cad-Cam system offers the possibility of manufacturing elements of different materials, with the most varied solutions: individual crowns, bridges, complete arches, structures to direct and indirect implants or with interfaces, anchors combined with studs, bars, etc.

All our experience in the Cad-Cam technique is at your service for the realization of structures, with a compensated design for its coating, by qualified dental technicians with experience and knowledge of many years in modeling in lost wax and thus we can design virtually stable structures: that are reinforced with a good offset design for support in the coating, and thus avoid unnecessary breakage or breakage.